Vacuum Infusion Process

Vacuum Infusion Process

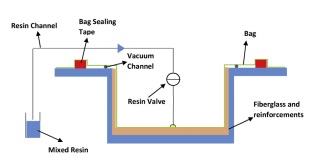

The FRP Vacuum Infusion Process is an advanced manufacturing method used to create high-quality fiber-reinforced polymer (FRP) components by using vacuum pressure to draw resin into dry reinforcement materials.

In this process, dry fibers such as fiberglass are carefully placed inside a mold, sealed with a vacuum bag, and infused with resin as the vacuum pulls it evenly through the material.

This technique ensures excellent control over the resin-to-fiber ratio, resulting in stronger, lighter, and more consistent FRP parts with a superior surface finish and high structural integrity.