Compression moulding

Compression Moulding

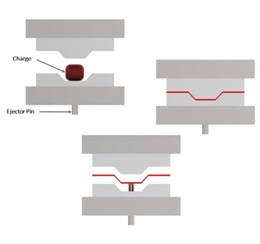

The DMC compression molding process involves placing a measured amount of dough molding compound (DMC) into a heated mold,

closing the mold with a heated plug to force the compound into the cavities, and then curing it with heat and pressure

until it hardens. The final step is to eject the finished, hardened part from the mold.

This is a thermosetting process that uses heat and pressure to mold plastic parts, especially for applications needing

good electrical insulation and moderate strength, such as switchgear and meter housings.